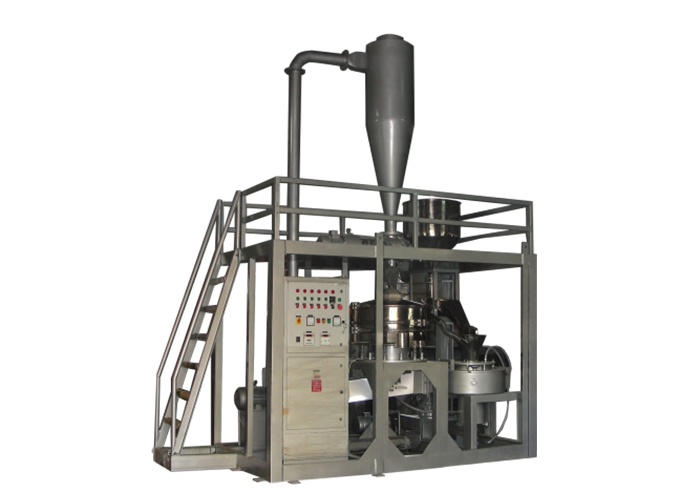

Bi-Axial Rotational Moulding Machine

- > Advanced designed Machine.

- > Fully automatic & compact for consistent quality product.

- > Sturdy & Unique mechanical design for trouble free running.

- > High efficient heating chamber for the best FUEL Economy.

- > All electrical/mechanical safety interlock for safe working.

- > High efficient LPG/DIESEL burner for fuel economy.

- > Specially design blowers to work under high temperature.

- > Unique design for easy maintenance.

| Model | No. of Arms | Loading of Vertical Mould | Power HP | Oven Size m | Cooling System | Fuel | Machine Space Require (L x W x H) m |

||

| Strai-ght | Off-set | Straight Arm | Off-set Arm | ||||||

| BRS-1 | 1 | NIL | 200/300/ 500L x 4 Nos. | NA | 11.0 | 3.6 x 3.6 x 15 | Air | LPG / Diesel | 10 x7 x 6 |

| OR | |||||||||

| 750/1000 L x 2 Nos. | |||||||||

| BRS-2 | 1 | Nil | 750/1000 L x 4 Nos. | NA x 1 No. | 17.0 | 4.5 x 4.5 x 1.8 | Air | LPG / Diesel | 12 x 8 x 8 |

| OR | |||||||||

| 1500/2000 L x 2 Nos. | |||||||||

| BRS-5 | NIL | 1 | NA | 3000/5000 L x 1 No. | 16.5 | 3.6 x 3.6 x 2.75 | Air | LPG / Diesel | 12 x 9 x 6 |

| BRS-10 | NIL | 1 | NA x 4 Nos. | 7500/10000 L x 1 No. | 24.0 | 4.5 x 4.5 x 3.5 | Air | LPG/Diesel | 15 x 10 x 8 |

| BRM-2-2S | 2 | 1 | 200/300/500 L x 4 Nos. | 1500/2000L x 1 No. | 26.5 | 3.6 x 3.6 x 2.0 | Air | LPG / Diesel | 14 x 12 x 6 |

| OR | |||||||||

| 750/1000L x 2 Nos. | |||||||||

| BRM-2-3S | 3 | Nil | 750/1000 L x 4 Nos. | NA | 45.0 | 4.5 x 4.5 x 1.8 | Air | LPG / Diesel | 21 x 14 x 7 |

| OR | |||||||||

| 1500/2000 L x 2 Nos. | |||||||||

| BRM-5 | 2 | 1 | 200/300 L x 6 Nos x 6 Nos. | 1500 to 5000 L x 1 No. | 35.5 | 3.6 x 3.6 x 2.75 | Air | LPG / Diesel | 16 x 12 x 6 |

| OR | |||||||||

| 500 L x 4 Nos. | |||||||||

| OR | |||||||||

| 750/1000 L x 2 Nos. | |||||||||

Note :

- > Continuous Quality Improvement is our motto.

- > Specifications are subject to change.

- > Customised Variants viz. 4 Arm / 2 Arm / Multiple Arm / Independent Arm available on request

- > PLC based control Panel available on request